Applications Rationing of materials

Rationing of materials

The Materials Rationing program is intended for assigning a workpiece to a part, automating the calculation of the consumption rate of the base material.

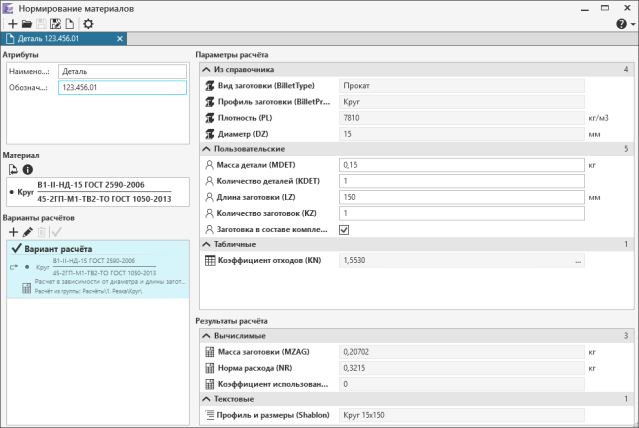

When calculating the workpiece, allowances for processing, non-multiplicity of the dimensions of the supplied material and other standards for technological losses are taken into account. Depending on the type and profile of the workpiece, the user is given the opportunity to select the required type of calculation. To optimize the consumption of materials, it is possible to perform several calculation options with the choice of the optimal one. Previous calculation options are saved in the document.

In the basic delivery of the system, algorithms for calculating blanks obtained by cutting rolled products and hot forging on hammers and presses, as well as hot stamping on hammers, are configured.

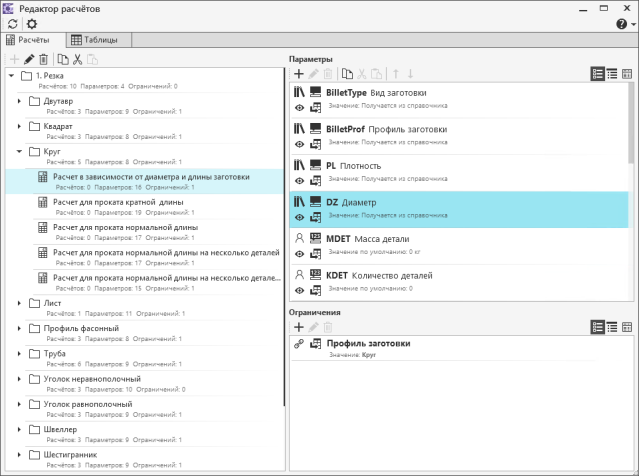

The built-in calculation editor ensures that the user enters the material standardization algorithms used in the enterprise.

The system allows you to configure to meet the requirements of tasks solved at the enterprise. Including:

- edit calculation algorithms from the base delivery;

- create and edit new calculation algorithms;

- configure tabular parameters and conditions for selecting values;

- configure the units of measurement for parameters.

The system also allows you to set up the calculation of the consumption rates of auxiliary materials and related rationing parameters.

The software interface provides integration with various systems.

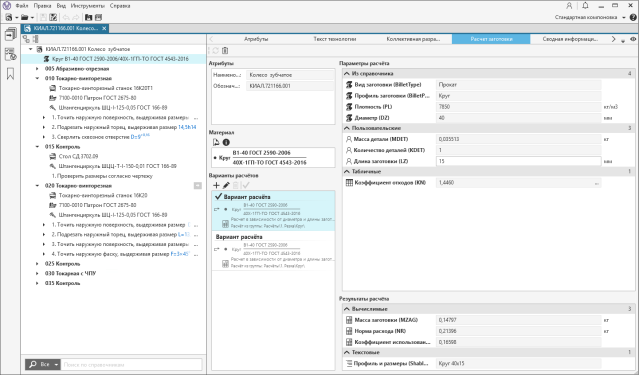

As part of the automation complex for design and technological preparation, the System is integrated:

- with “POLYNOM:MDM Materials and Assortments” to obtain the necessary data on the materials and assortments used at the enterprise, including profile dimensions and material properties;

- with the LOTSMAN:PLM system for the formation of process sheets for the consumption of materials, data transfer to various systems for the preparation, planning and production management of the MRP II\ERP class;

- with CAD TP VERTICAL:

- to obtain initial data for calculation from the process design;

- to save the calculation results.

Video “Calculation depending on the diameter and length of the workpiece”

https://ascon.ru/products/895/