Applications Rationing of labor costs

Applications:

Rationing of labor costs

The program Normalization of labor costs solves the problem of automated calculation of the time spent on technological operations.

The system is based on an interactive method of working with tabular data, thanks to which it solves the problems of automated calculation of the time spent on technological operations in the following ways.

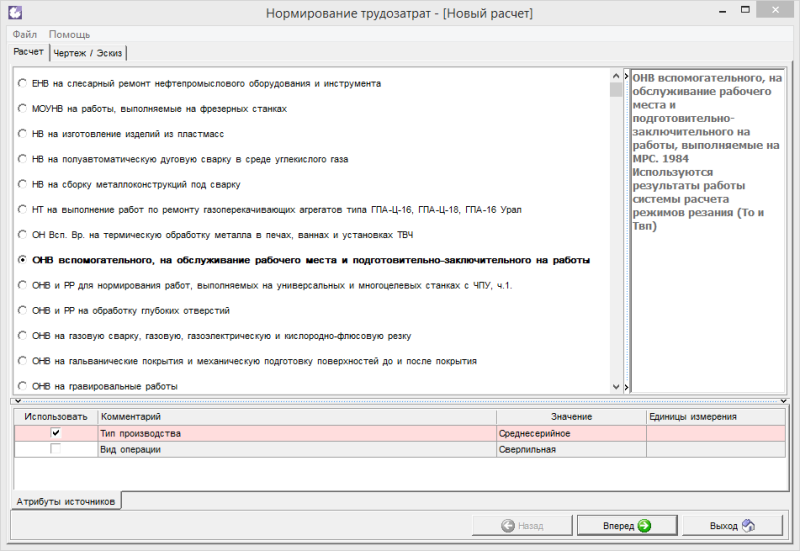

In the first case, the source of calculation is the aggregated norms, and as a result, the values of the preparatory and final time, the sum of the incomplete piece and auxiliary time for such types of work as assembly, cutting, pressure, coating, movement, general operations, technical control and others

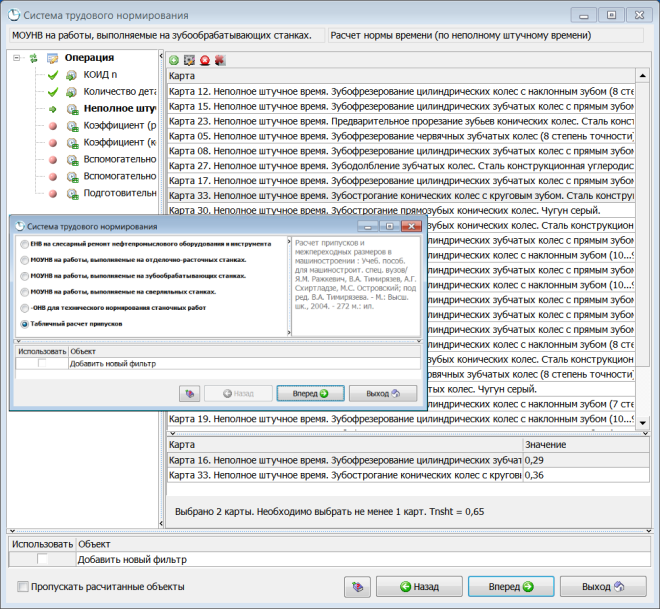

According to the data from the technical process, the system finds the most suitable sources and the corresponding labor rationing maps. Based on the transition parameters, the user determines the piece time using the card selected from the list. Further, in most cases, it is necessary to apply correction factors that take into account the state of the surface of the workpiece, the hardness of the material and other factors. Incomplete piece time is automatically calculated according to a formula that takes into account all the card correction factors. The summation of the piece time for the operation is performed automatically. After the calculation is completed, information about the selected maps, parameters and results of the calculation is transferred either to the technical process of the VERTICAL system, or is stored in the VERTICAL-Reports card (*.vrp).

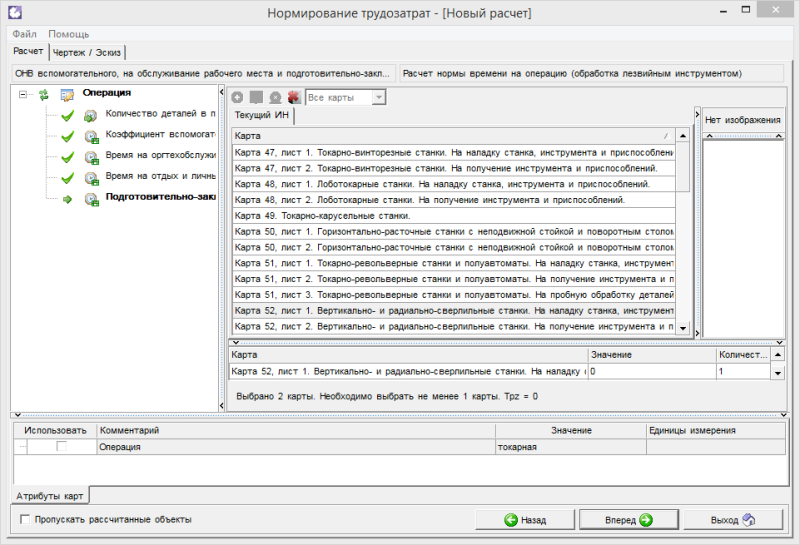

In the second version of the work, the system determines the norms of time for the so-called machine work, calculates the auxiliary time for installing and removing the part, the auxiliary time for control measurements, preparatory-final and piece-calculation time for technological transitions of machining.

The results of calculations and information about the applied maps are stored in the process. Complete with modules for calculating processing modes (for example, with the program Calculating cutting conditions), the program Labor cost rationing provides accurate rationing of the execution time of operational technological processes.

The program provides for the possibility of developing and connecting custom maps for labor rationing, tables of correction factors, and adjusting the formulas used to calculate part-time work. The system fully supports work with normalization maps that have complex (composite) table headers, including those with images.