Applications Cutting data calculation

Cutting data calculation

Application Calculation of cutting conditions is intended for:

- automated calculation of material processing parameters;

- calculation of auxiliary time for the main transition of the technological operation of the developed technical process;

- editing and creating new algorithms and methods for calculating cutting conditions;

- tool selection from the SANDVIK POLYNOMIAL:MDM catalog.

The system consists of three separate modules:

- Calculation of cutting conditions;

- Cutting data configurator;

- Sandvik tool selection.

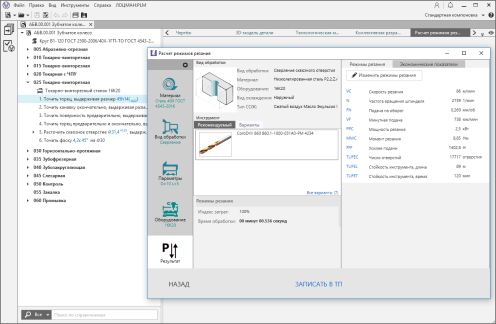

The module Calculation of cutting conditions can be launched both as a standalone Windows application and from the CAD TP VERTICAL technical process.

Module features:

- calculation of cutting conditions for various types of processing;

- auxiliary time calculation;

- flexible adjustment of calculation results;

- graphical representation of processing;

- debugging calculation algorithms.

The main formulas and calculation methods used in the system are taken from the following publications:

- HELL. Loktev, I.D. Gushchin, V.A. Batuev and others. General machine-building standards for cutting modes: A reference book in 2 volumes. – M .: Mashinostroenie, 1991.

- Metal cutting modes. Directory. Ed. Yu.V. Baranovsky. Ed. 3rd, revised and expanded. M., “Engineering”, 1972.

- Kashchuk V. A., Vereshchagin A. B. Handbook of a grinder. — M.: Mashinostroenie, 1988. — 480 p.: ill.

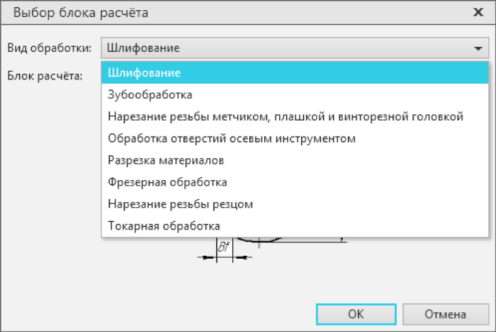

The application allows you to calculate cutting conditions for the following types of processing:

- grinding;

- tooth processing;

- threading with a tap, a die and a screw-cutting head;

- machining holes with an axial tool;

- cutting materials;

- milling;

- cutting thread with a cutter;

- turning.

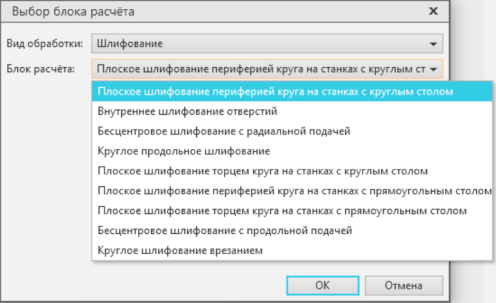

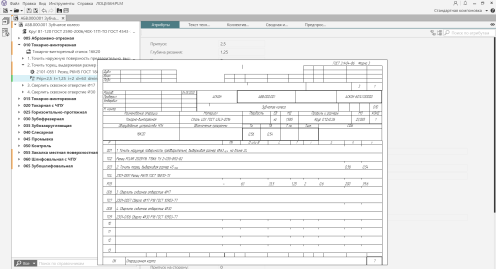

For each type of processing, it is possible to assign different calculation blocks for different types of technological operations.

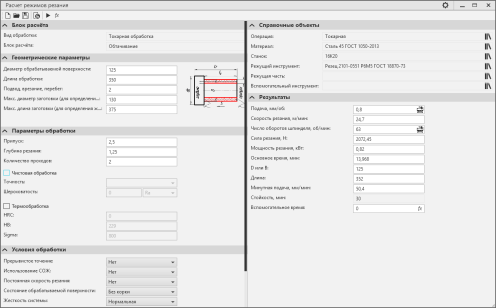

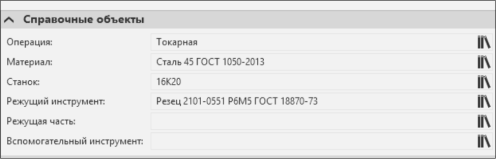

Initial data for calculation:

- operation;

- materials;

- machine;

- cutting tool;

- cutting part;

- auxiliary tool,

can be obtained from CAD TP VERTICAL or manually selected from the corresponding catalogs and groups of directories POLYNOMIAL:MDM.

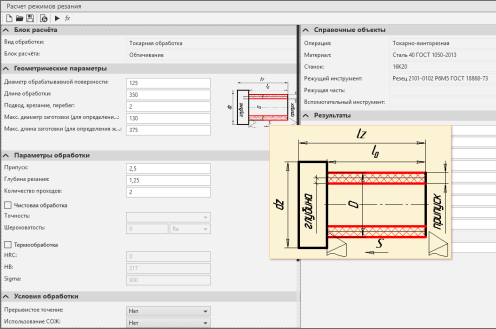

Also, for the calculation, it is required to enter various geometric parameters and processing parameters:

- allowance;

- cutting depth;

- number of passes.

For finishing, it is necessary to enter the accuracy and roughness of the surface, the parameters of the workpiece after heat treatment – hardness and strength, and also enter the processing conditions:

- coolant use;

- condition of the treated surface;

- system rigidity, etc.

For the convenience of assigning geometric parameters for the selected calculation block, the system displays the processing scheme.

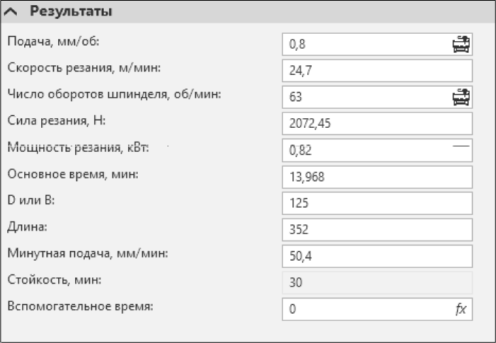

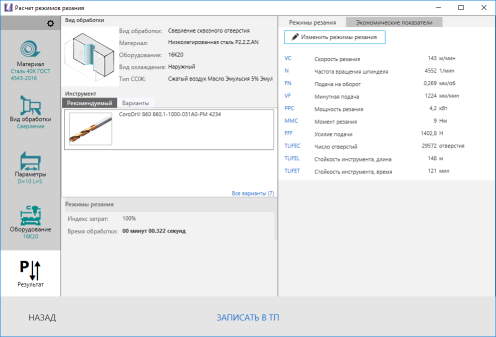

For the entered initial data, we obtain the following calculation results, in our case for turning the surface on a lathe:

- filing;

- cutting speed;

- spindle speed;

- cutting force and power;

- tool durability.

For the results obtained, the system allows for manual adjustment of the feed and the number of revolutions of the spindle according to the capabilities of the specified equipment.

The results obtained, if necessary, can be saved in a separate file. And if the calculation was launched from the technical process CAD TP VERTICAL, the calculation data can be transferred and saved in the file of the developed document of the technical process. At the same time, when changing the parameters of a technological operation, for example, when changing a tool or equipment, the system automatically recalculates with the new parameters.

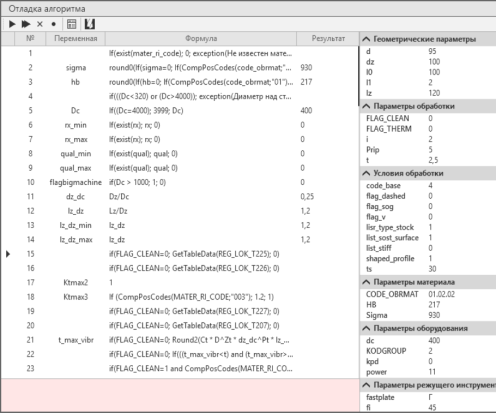

To develop new and edit methods from the delivery, it is always required to debug the introduced algorithm. To do this, the system offers in a specialized window “Debugging the algorithm” the possibility of step-by-step execution of the algorithm with the function of monitoring intermediate results.

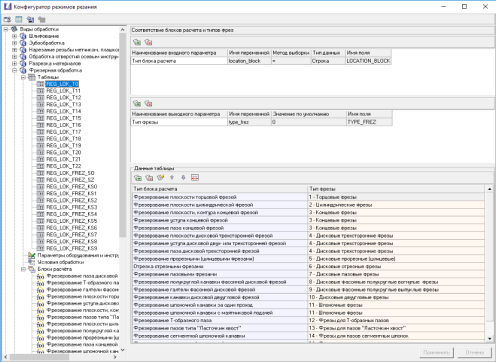

Cutting data configurator module

The calculation of cutting conditions is carried out in accordance with algorithms and tabular data, the description of which is stored in the system database.

To edit this data, there is a separate application – Cutting Data Configurator.

The application allows you to create new and edit existing algorithms and data for calculating cutting conditions for various types of processing used in the enterprise.

Sandvik Tool Selection Module

The tool selection module, which is part of the application, allows for drilling and milling operations to solve the tasks of selecting Sandvik tools from the NSI POLYNOM: MDM control system, taking into account the characteristics of the material being processed, the geometric parameters of the element being machined, fastening conditions, the type of cutting fluid, and the assignment of processing modes for it and calculating the auxiliary time associated with the transition.

The module is integrated with the CAD system TP VERTICAL. The initial data for calculating cutting conditions is obtained from the description of the technological transition of the technical process by CAD TP VERTICAL. The results of the application can be transferred to the project of the CAD TP VERTICAL technical process.

Video “Calculation of cutting data”