DESIGN OF TECHNOLOGICAL PROCESSES

DESIGN OF TECHNOLOGICAL PROCESSES

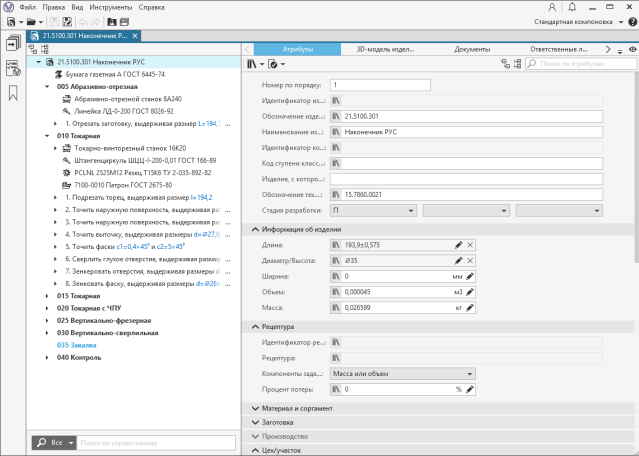

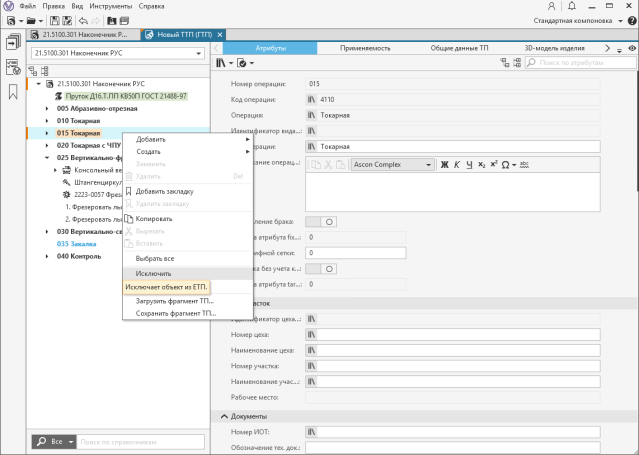

The VERTICAL system allows you to design technological processes in an automated mode, which are based on a hierarchical structure of operations, transitions, equipment, professions, tooling and other technological objects, and also provides the possibility of parallel design of complex and end-to-end technical processes by a group of technologists in real time.

The development of standard and group technological processes is supported, within the framework of which it is possible, once filling in the general data of the technological process, to use them later to design many single technological processes. The system also supports the creation of standard and group technical processes based on a previously developed single one.

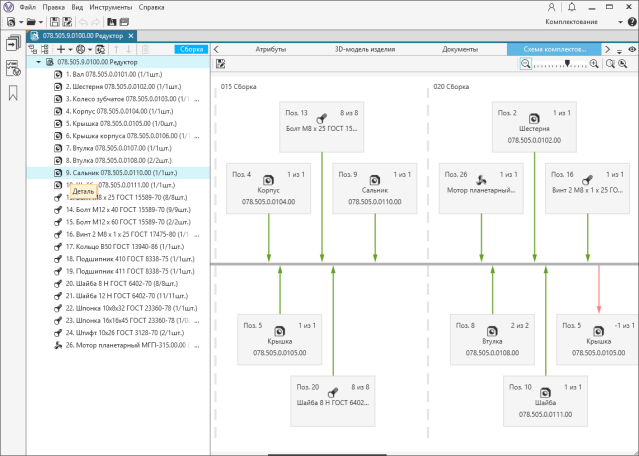

The specialized layout of the Vertical interface allows you to develop assembly technological processes, including using a graphical scheme for completing operations and transitions

As part of the work with the VERTICAL system, the relevance of technological information is maintained using change management processes.

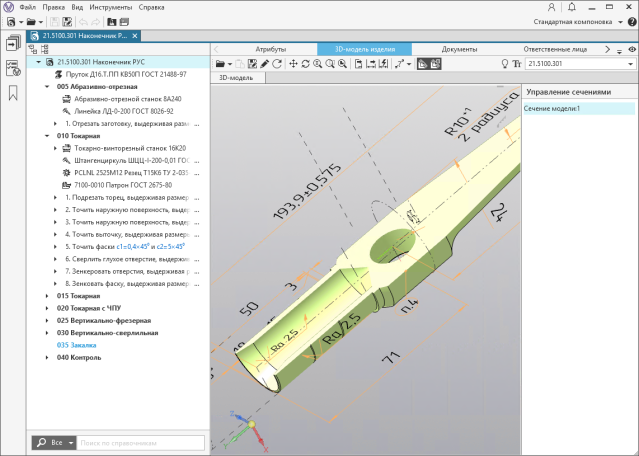

The system supports two-way communication of technological process parameters with the parameters of KOMPAS-3D graphic documents: drawings, sketches, 3D models. When changing the values of parameters in graphic documents, there is a corresponding change in the associated parameters of the technological process (for example, changing the dimensions in the text of the transition when changing the corresponding dimension in the drawing). There is also the possibility of the reverse action – updating the parameter value in the graphic document in response to changes in the TP.

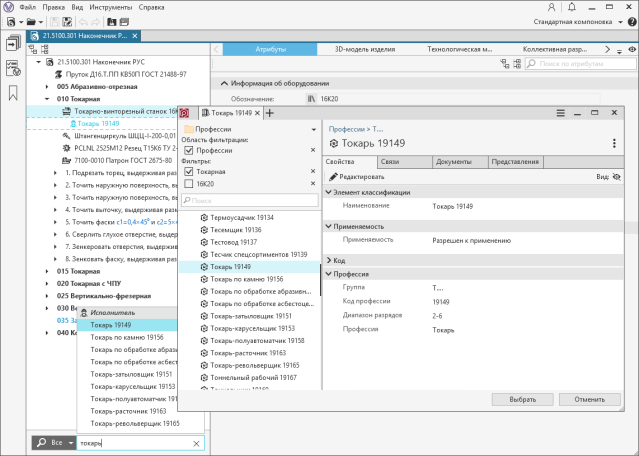

VERTICAL supports seamless integration with the POLYNOM:MDM reference information management system. The search system implemented in VERTICAL allows you to find, add and replace process objects directly from POLYNOM:MDM directories without opening the system window. In this case, the search is carried out among those objects that can be applied taking into account the configured process model.

FORMATION OF ORDERS FOR THE DESIGN OF SERVICE STATIONS AND THE CREATION OF CONTROL PROGRAMS FOR CNC EQUIPMENT

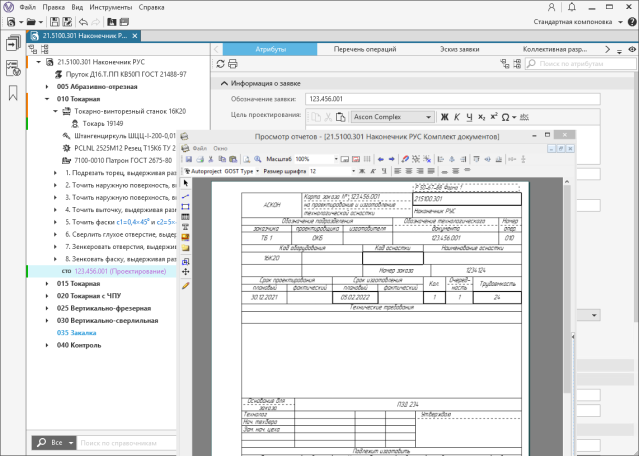

The VERTICAL system implements the functions of generating applications for the design of technological equipment (STO) and control programs (CP) for CNC equipment. After the formation of the application, they are sent for approval to the relevant services, while the approval of applications is possible when working with the LOTSMAN:PLM system.

TECHNOLOGICAL CALCULATIONS

Specialized applications* allow you to perform calculations in various areas of technological preparation of production:

* Supplied separately

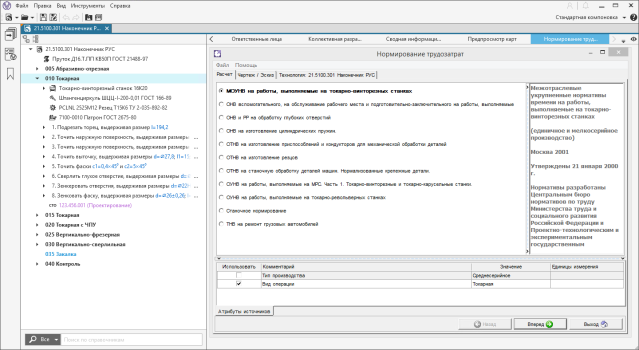

Rationing of labor costs

Application Rationing of labor costs solves the problem of automated calculation of the time spent on technological operations. The system implements various methods of calculation depending on the degree of consolidation of labor costs (differentiated, enlarged, typical) from more than 50 collections of labor standards for various types of work (assembly, cutting, pressure, coating, welding, heat treatment, general operations). appointments, technical control, etc.)

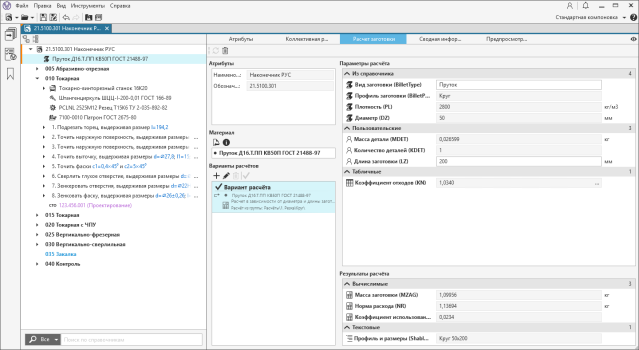

Rationing of materials

Material rationing is a universal application that allows you to create and edit calculations to solve a wide range of material rationing problems in close integration with VERTICAL.

The application allows you to solve the tasks of assigning a workpiece to a part, calculating the mass of a workpiece, automating the calculation of the consumption rate of the main material and other rationing parameters in the technological divisions of the enterprise.

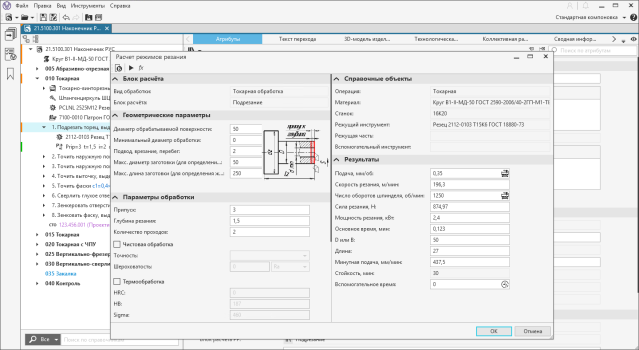

Cutting data calculation

Cutting data calculation is an application designed to:

- for automated calculation of material processing parameters

- for selecting a tool depending on the characteristics of the material being processed, the geometric parameters of the element being processed, fastening conditions, the type of cutting fluid, calculating the processing modes, calculating the auxiliary time associated with the transition.

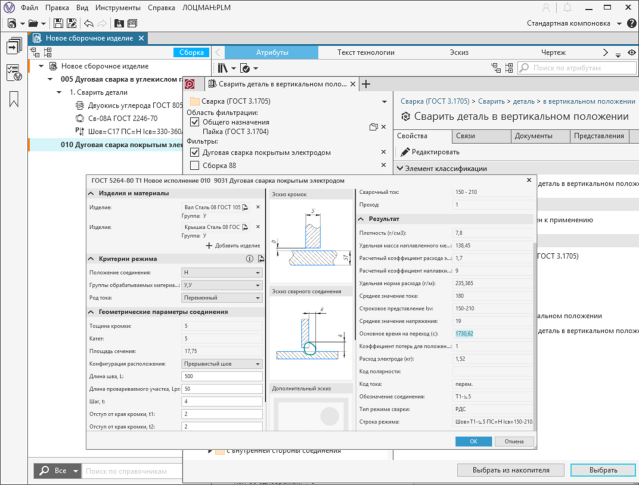

Calculation of welding modes

Calculation of welding modes is an application designed to automate the work of a technologist when designing a welding technology and supports work in the integration mode with CAD TP VERTICAL.

The program works in the CAD structure of technological processes VERTICAL and solves the following tasks:

- automated selection of modes for the main types of welding;

- automated selection of welding materials;

- calculation of consumption rates of welding materials;

- calculation and main time for technological transition;

- setting of all parameters and data processing algorithms for any welds and welding methods.

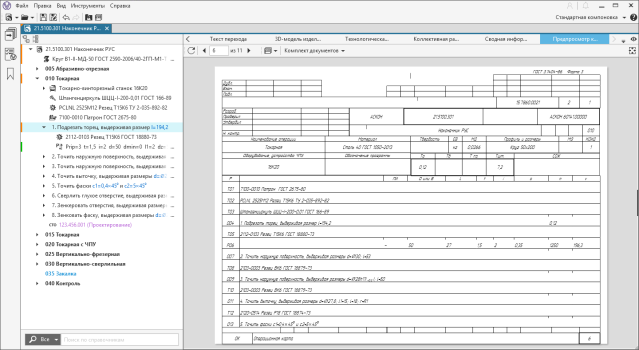

FORMATION OF TECHNOLOGICAL DOCUMENTATION IN ACCORDANCE WITH THE REQUIREMENTS OF GOST RF AND THE STANDARDS USED AT THE ENTERPRISE

After the completion of the development of the technological process, which contains all the necessary information for the production of the product, the VERTICAL system allows you to automatically generate a set of technological documentation. The basic delivery of the system contains most of the forms of documents provided for by GOST of the ESKD series (technological charts and statements).

The Map Preview tab allows the user to visually evaluate how the data of the current project tree object will be displayed in documents. On the tab, you can display both the entire set of maps and a filtered list of maps associated with process objects.

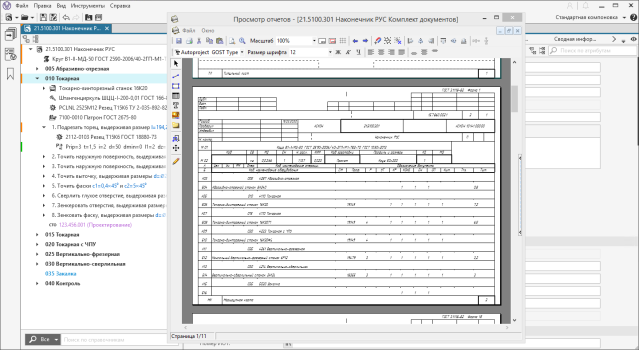

The VERTICAL-Reports module allows you to create new reporting forms and data selection algorithms for placement on the form according to the requirements of the enterprise of almost any complexity.

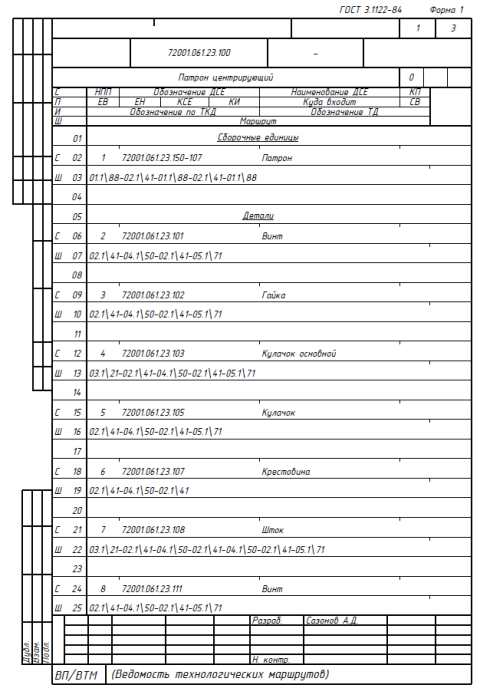

A set of technological documents for a product may include documents containing information not only from a single technical process, but also summary technological information on all components of the product. As a rule, these are various statements, for example, a statement of specified consumption rates, a statement of materials, a statement of routes.

SUPPORT FOR A SINGLE INFORMATION SPACE FOR PRODUCT LIFECYCLE MANAGEMENT

The VERTICAL system can be used at the enterprise as an independent tool for solving problems of technological preparation of production, as well as integrated with other ASCON products, which allows the system to be included in a single CT3D solution for product life cycle management and create a digital environment for joint product development and production preparation. As a result, the electronic product description contains the complete information necessary to support the stages of the product life cycle. At the pre-production stage, the accumulation of data on the results of design and technological design and the exchange of information between engineering services is ensured.

https://ascon.ru/products/420/review/