PILOTMAN:PLM

PILOTMAN:PLM

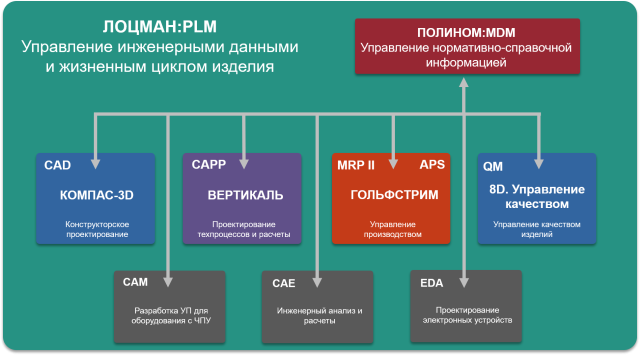

The engineering data and product life cycle management system LOTSMAN:PLM plays a coordinating role within the ASCON software package for mechanical engineering. Its task is to combine the business processes of the enterprise, the work of engineering departments and the use of software solutions into a single product development process.

LOTSMAN:PLM is a platform that includes basic tools and application modules for solving a wide range of tasks.

DATA AND CHANGE MANAGEMENT

The key task of LOTSMAN:PLM is to manage data, which are interconnected information objects and documents describing the design, characteristics, manufacturing technology and other information about the product, as well as data on employees, departments and business processes within the engineering activities of the enterprise.

Interacting with other systems, LOTSMAN:PLM covers the entire spectrum of engineering data management from requirements management and product design to technological preparation and transfer to production.

The system also allows you to make changes in data and documentation at each stage and provides the ability to manage electronic and mixed document management of the enterprise.

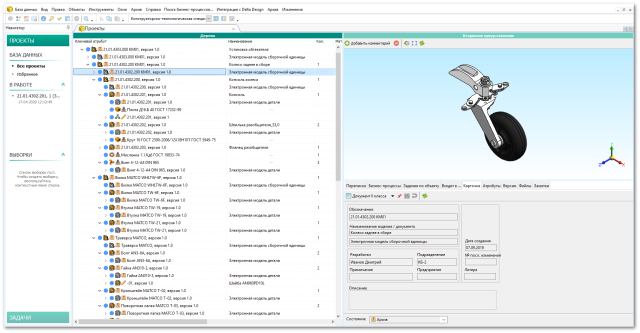

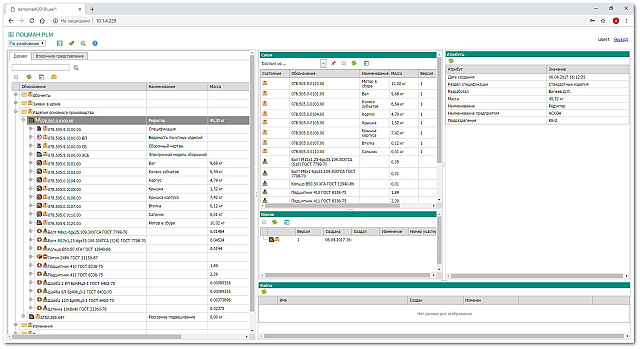

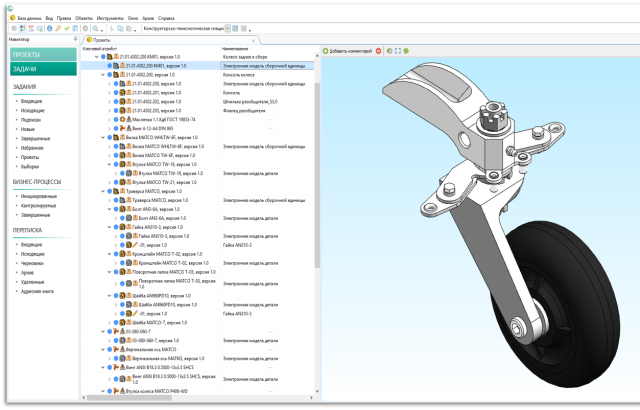

Work in LOTSMAN:PLM is possible both through a standard desktop application and through a web client.

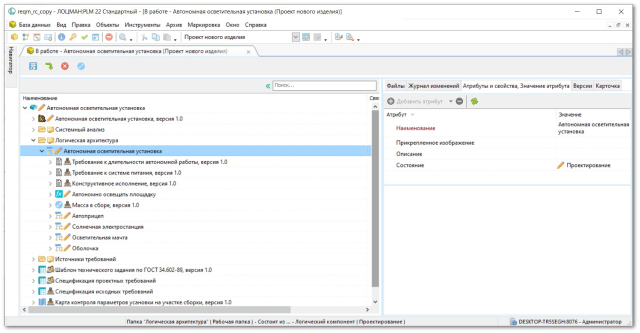

PRODUCT STRUCTURE AND CONFIGURATION MANAGEMENT

The basis of the electronic description of the product is its electronic structure. In LOTSMAN:PLM, the electronic structure of a product is a hierarchically linked set of information objects of various types, depending on the type of this structure.

The constructive electronic structure of the product is represented by such elements as assembly units, complexes, parts, standard and other products, kits. The technological structure may additionally include technological assemblies, with the help of which the components are structured in one way or another, taking into account the features of the manufacture of the product (for example, the assembly sequence).

The formation of the electronic structure of the product is possible both by creating information objects by the user in the LOTSMAN:PLM interface, and by automatically creating them based on information from CAD systems.

Configuration management mechanisms in LOTSMAN:PLM allow you to create multivariant product structures, eliminating the need to describe each variant in full, instead describing only the differences (options, replacements, variants).

LOTSMAN:PLM can work with both static and dynamic product structures. Working with dynamic structures is especially important when designing complex products, when there are a lot of changes that take into account design options and individual features of products supplied to customers. Such changes generate a large number of versions of the components included in the product structure. Accordingly, it is required at any time to obtain the structure of the product according to the given conditions. For example, a product breakdown that was in effect on a specific date or for a specific end product instance number. To solve such problems, LOTSMAN:PLM implements the configuration of dynamic structures according to their applicability.

REQUIREMENTS MANAGEMENT

Mechanical engineering products are often technically complex mechanisms. They are used in various conditions and situations, which imposes certain requirements on them. Requirements can be imposed not only on the product itself and its components, but also on the manufacturing and operation processes. For example, the requirements for using the product in certain climatic conditions.

The task of collecting, classifying and implementing requirements can be complex and require appropriate software tools. In the ASCON software package, this task is solved by the requirements management subsystem LOTSMAN:PLM.

Product requirements are both individual LOTSMAN:PLM objects with attributes, properties and descriptions, as well as entire requirements specifications. A product requirement may have an associated source that it relies on, such as a document or a document fragment. The source in the LOTSMAN:PLM system is a versioned object and can be updated and revised.

The extended data model of the requirements management subsystem allows you to create a logical architecture of a future product and combine requirements around logical components (product components) or logical functions (component functions), thereby implementing a systematic approach to design.

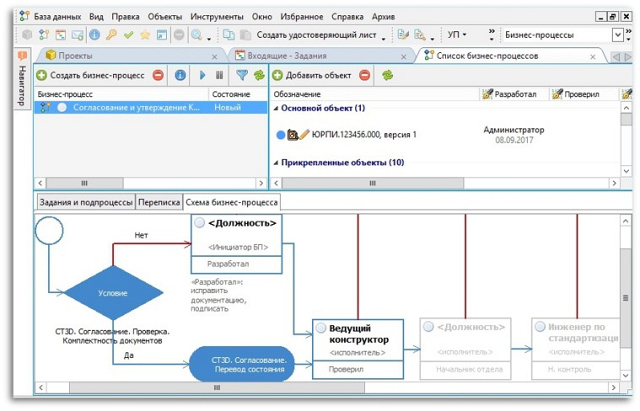

BUSINESS PROCESS MANAGEMENT AND COMMUNICATION

LOTSMAN:PLM provides management of enterprise business processes within the framework of engineering activities and allows each participant to receive initial data, record the results of their work and transfer tasks to other participants in the process.

Managers get the opportunity to monitor the progress of work and automatically receive notifications of scheduling conflicts and violation of project deadlines.

The built-in messaging system, applications and links to objects allows you to effectively communicate between specialists and manage workflows.

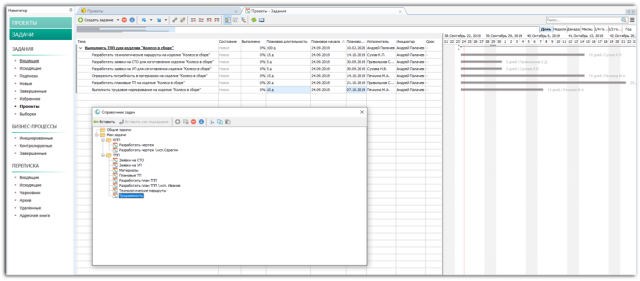

SCHEDULING AND PROJECT MANAGEMENT

Engineering processes require planning and control on an ongoing basis. The LOTSMAN:PLM functionality allows you to plan and track the performance of both individual tasks and their combinations at the level of individual specialists, divisions, departments and the entire organization.

The system allows you to form a plan in the form of a structure of interrelated works, link tasks to each other, set planned deadlines, assign performers, priorities. The display of the work plan is possible both in the form of a list and in the form of a Gantt chart, which makes it possible to more clearly determine the timing and conflicts of tasks.

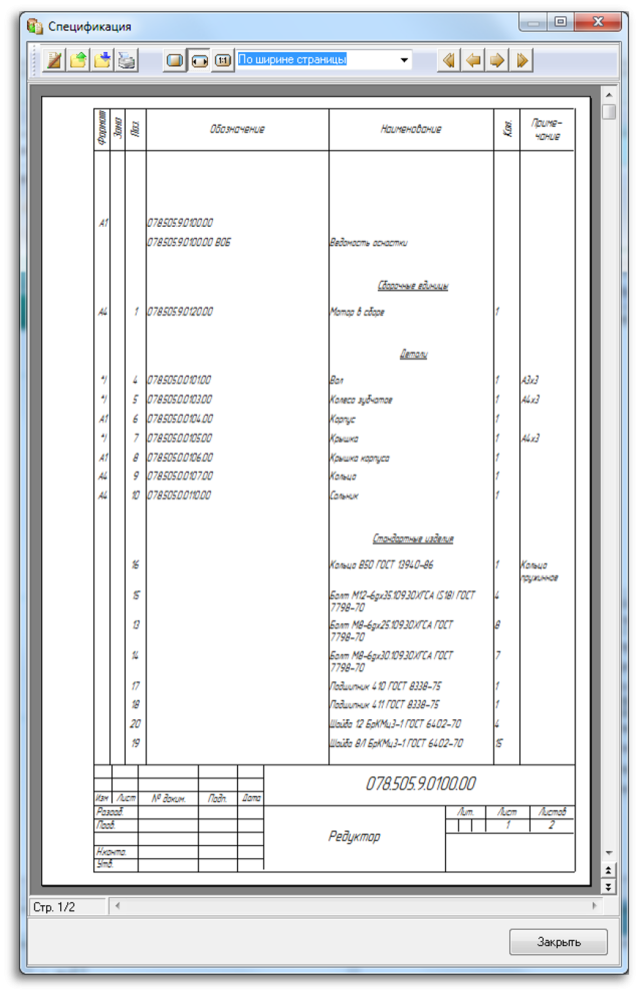

REPORTING AND DOCUMENT PRINTING

LOTSMAN:PLM provides the ability to generate reports in office application formats (Microsoft Office, OpenOffice, LibreOffice), as well as using the FastReport report generator. Also, enterprises can independently, or with the involvement of an integrator, implement a unique logic for selecting data for output to reports using scripts, customize arbitrary report templates in accordance with the requirements of enterprise standards.

The most common standardized reports in accordance with the requirements of the standards of the ESKD and ESTD series are delivered ready-made (for example, a design specification, a list of purchased products, a list of materials, etc.).

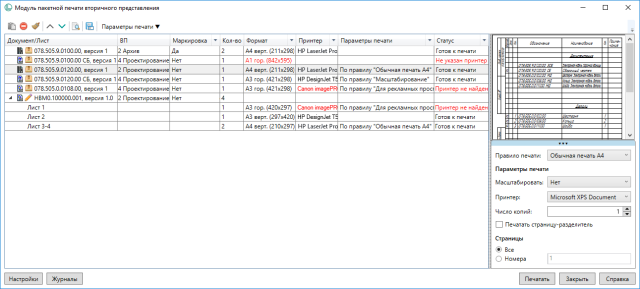

The system also provides the ability to batch print 2D documents based on the universal PDF format with flexible rule settings.

INTERACTION WITH OTHER SYSTEMS

Universal integration mechanisms LOTSMAN:PLM allow the system to interact both with ASCON solutions within a single software package, and with products from other developers.

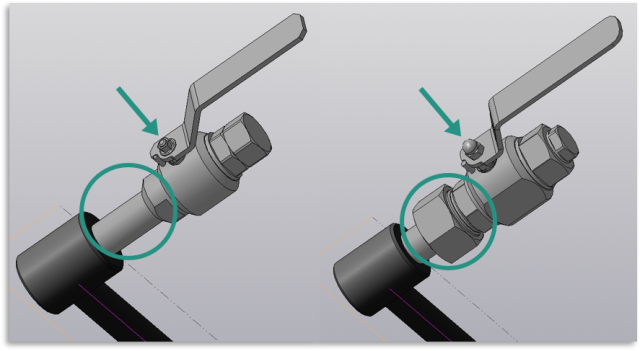

The closest integration is implemented for KOMPAS-3D, VERTICAL, POLYNOM:MDM systems and other ASCON solutions. In these bundles, information exchange mechanisms are implemented taking into account the requirements of domestic standards (ESKD, ESTD).

For example, in the integration links between LOTSMAN:PLM and KOMPAS-3D for such documents as a design specification, an assembly drawing, an electronic model of an assembly unit, the requirements of ESKD for positioning positions, designing zones on drawings, recording data in various sections of the specification, recording acceptable replacements are taken into account and substitute materials. These requirements are taken into account in such a way that the user’s work is automated and there is no need to re-enter data in various documents.