SCIENCE IN MANUFACTURING PILOTMAN PLM

PAYMENT

PILOTMAN:PLM

Applications LOTSMAN:PLM Technology

LOTSMAN:PLM Technology

A set of applied modules LOTSMAN:PLM for technological preparation of production (hereinafter referred to as TPP) is designed to manage technological data: production and technological electronic structures of products, intershop technological routes, materials, technological processes, requests for tooling design and development of control programs.

It consists of the module PILOT:PLM Technology and the module PILOT:PLM Planning CCI*.

1. POSSIBILITIES OF THE LOTSMAN:PLM MODULE TECHNOLOGY:

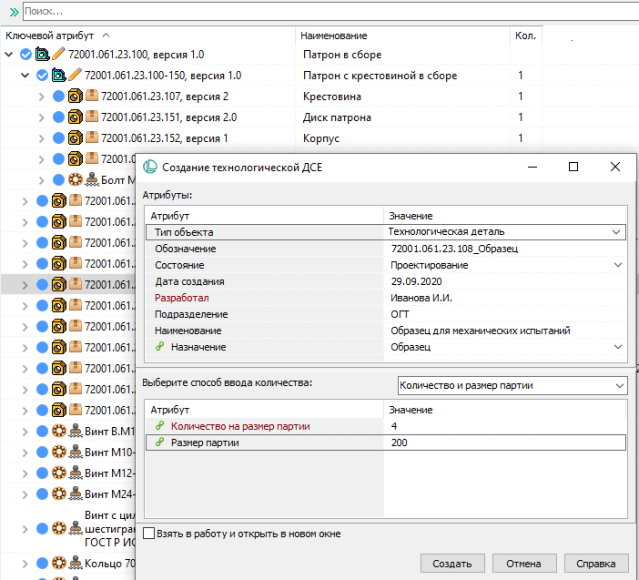

- formation of the production and technological electronic structure of the product, including an indication of the needs for technological DSE (samples, witness samples, test kits);

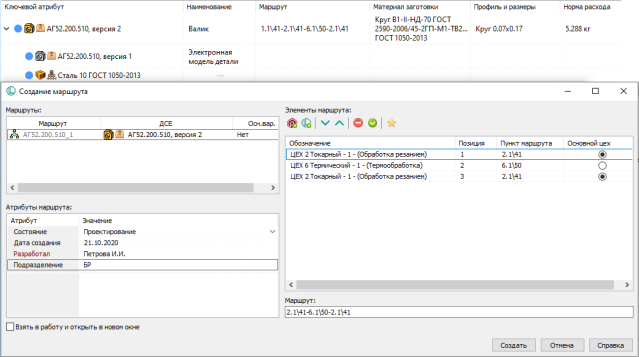

- creation and editing of intershop technological routes (including by analogy and for a group of parts and assembly units) with the ability to specify the main shop (manufacturer’s shop) and alternative route options;

- comparison of route and technological process;

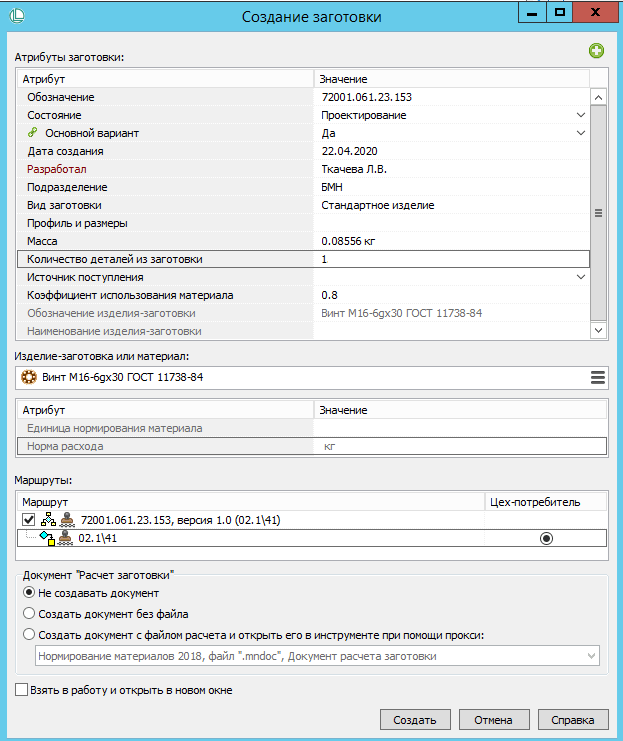

- creating and editing data on blanks with the ability to work with analogues, alternatives and specify a part, standard or other product as a blank;

- determination of the consumption rates of the main and auxiliary materials in the manual entry mode or through integration with the Materials rationing system;

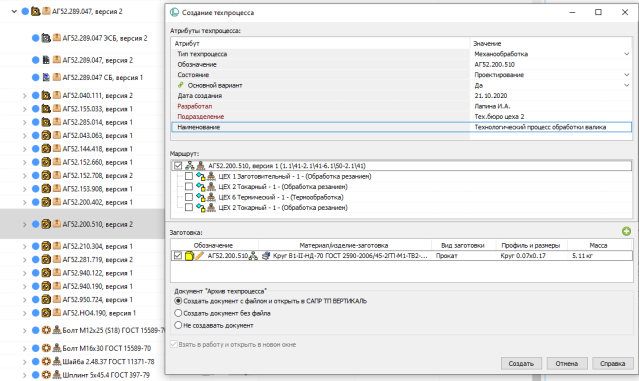

- creation of single, standard and group technological processes (information objects LOTSMAN:PLM with documents and files of CAD TP VERTICAL), setting up a connection with a route/route element and a workpiece/semi-finished product, opening for editing in CAD TP VERTICAL.

Material consumption rates can be calculated at the stage of development of technological processes in CAD TP VERTICAL. The choice of solution architecture depends on the organizational features and processes of the enterprise.

2. POSSIBILITIES OF THE MODULE LOTSMAN:PLM PLANNING OF THE CCI:

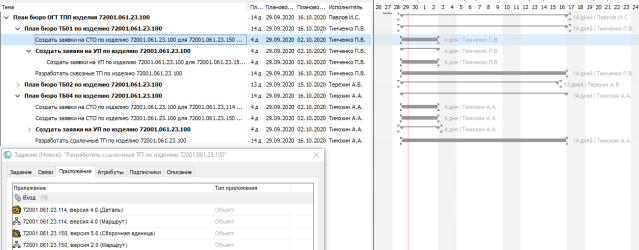

- automated formation of plans for shop technological groups / CDP bureaus specialized in types of processing, based on inter-shop technological routes for the manufacture of product components;

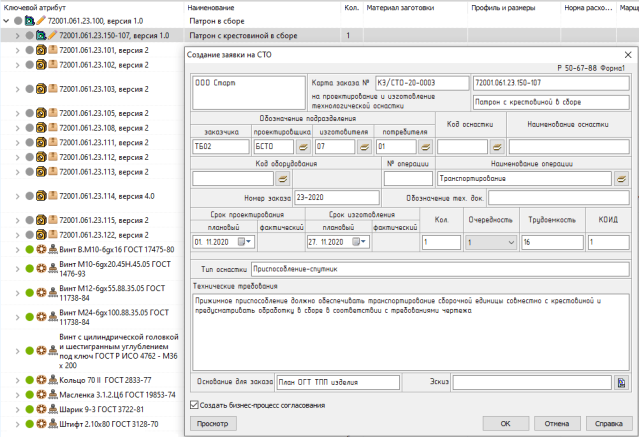

- formation of applications for the design of technological equipment and the development of control programs for CNC machines with the possibility of automatically launching the approval business process;

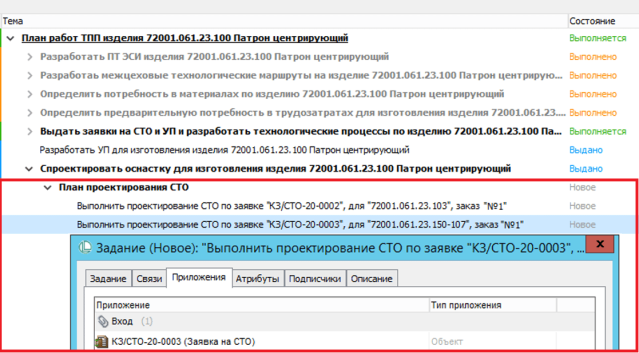

- automated generation of plans for the design bureau of technological equipment and development of control programs based on the relevant approved applications with automatic launch of business processes for registering equipment in the directory (in the case of a plan for applications for service stations) upon completion of the task.