KOMPAS-Electric

KOMPAS-Electric

To date, hundreds of enterprises in Russia and neighboring countries are successfully designing electrical equipment using the KOMPAS-Electric system. There are two variants of the system: KOMPAS-Electric and KOMPAS-Electric Express.

KOMPAS-Electric is intended for:

- to automate the design and release of a set of documents (diagrams and reports to them) for electrical equipment of production facilities in which wired installation is used to perform electrical connections (low-voltage complete devices (LCD), relay protection and automation systems (RPA), automated control systems for technological processes, etc.) d.);

- to automate the design of a set of documents for electrical equipment of production facilities using programmable logic controllers (PLC).

The system can be used in institutes, design bureaus and departments that design electric drives, non-standard equipment, develop power supply projects in industrial and civil construction.

When using KOMPAS-Electric, the following positive effects are achieved:

- the speed of creating and processing project documents is increased: the system has the functions of automatic generation of most of the documents;

- the quality of paperwork is improved: all graphic designations of electric devices in all project documents are brought to a single representation, the design elements of drawings fully comply with the requirements of ESKD.

The system consists of two main modules: Database and Schema and Report Editor.

The system database contains components used in projects, as well as conventional graphic symbols (UGOs) used when creating electrical circuit diagrams. The database already has initial content – about 6000 product types and about 600 graphic symbols. At any time, you can add new components and UGO to it. The base can work on the DBMS platform Microsoft SQL Server, Microsoft Access, Borland InterBase, Oracle. The system also includes a database of Schneider Electric products, which contains more than 1800 components and their descriptions.

Other component databases can be downloaded from the link https://sd.ascon.ru/otrs/public.pl?Action=PublicFAQZoom;ItemID=773

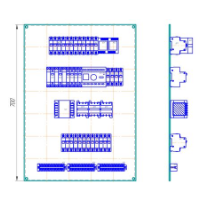

Project documents are created, edited, prepared and printed out in the Scheme and Report Editor. Among them are the Electrical Schematic (E3), Connection Diagram (E4), Layout Diagram (E7), Lists of Elements, Specifications, Tables of Connections and Connections and much more. To manage projects and their documents, the Editor provides a Project Manager. The editor of schemes and reports operates in the environment of the KOMPAS-Graph system.

The main functions of KOMPAS-Electric:

- insertion of UGO from the library into the circuit, its processing and execution of control operations;

- construction and editing of electrical communication lines, electrical buses, group communication lines;

- manual and automatic placement of wire marking;

- automatic arrangement of UGO on the electrical connection diagram, connection diagram and general diagram;

- semi-automatic generation of a technological map of the layout of wires;

- export of project documents to KOMPAS-Graph;

- adding 3D models and text documents of the KOMPAS system to the project;

- insertion of special symbols for communication lines (screen, cable, coaxial conductor, twist, etc.);

- optimization of wire laying routes;

- the function of centralized adjustment of electrical connections in the product;

- automatic generation of terminal blocks in the course of work on the project.

The Model Editor and the PLC Documentation Editor are used to design PLC operating documentation. With their help, you can add or edit PLC models, as well as design and calculate data for PLC operational documentation.

KOMPAS-Electric allows you to create specific types of documents to describe the operation of the PLC:

- PLC work program;

- connection diagram of PLC modules (inputs/outputs);

- clock cyclogram;

- list of PLC components;

- PLC memory allocation table;

- list of errors in the program of work;

- change log.

Requires for work: KOMPAS-3D or KOMPAS-Graph