IOSO-K optimization

IOSO-K optimization

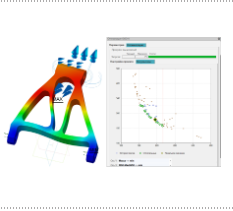

Application for optimizing the geometry of parts and assemblies in KOMPAS-3D.

Parameterization makes it possible to consider several variants of a product in one model. This is one of the benefits of 3D modeling. The question is which option to choose?

To answer it, the IOSO-K Optimization application was created.

Optimization is a directed search for the best solutions. And IOSO is a multidimensional non-linear optimization technology developed by SIGMA Technology. The advantages of the technology include:

- high speed of finding the optimal solution,

- simplicity (working with IOSO-K does not require special knowledge and settings).

Before you start optimizing, you need to ask yourself three questions:

- What do I want to do with the item? Increase its strength, reduce weight, improve hydraulic performance, etc.?

- Why do I want to achieve this? What do I need to change in the geometry (what parameters) to get the expected result?

- What restrictions should I consider? For example, the minimum margin of safety.

If the answers to all three questions are known, the optimization problem can be solved. The application can work both together with APM FEM and KompasFlow, and independently. When setting the optimization problem, you can set five parameters and two criteria.

Optimized options include:

- any variables in KOMPAS-3D,

- KompasFlow boundary conditions.

Optimization can touch criteria:

- mass and volume, surface area of the model,

- stresses and displacements in APM FEM,

- calculation results in KompasFlow.

Requires for work: KOMPAS-3D