CNC module. Turning

CNC module. Turning

CNC module. Turning is the first CAM application fully integrated into the KOMPAS-3D 3D modeling system. The application is designed to automate the development of control programs for CNC lathes (2-axis turning).

With the advent of the application, the entire process from designing a part to transferring a 3D model to a CNC machine takes place in a single KOMPAS-3D environment. For the enterprise, this means a reduction in the time for preparing products for production – there is no need to export data from KOMPAS-3D to CAM systems, there is no loss of time for conversion and error correction in case of incorrect transfer. There is not even a probable possibility of incorrect data transfer, and this is the key to success! The work of a process engineer is also simplified – he uses one 3D system, without being distracted by third-party applications, and is confident in the accuracy of the data on the basis of which the control program was developed.

The operation of the application as part of KOMPAS-3D allows you to automatically rebuild the control program for the CNC machine in case of a change in the geometry of the part.

The main features of the application:

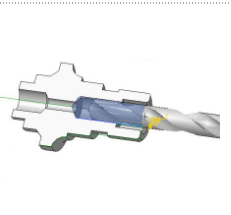

- construction of processing contours by visual selection of surfaces or sketches directly on a three-dimensional model created in the KOMPAS-3D system;

- automatic calculation of trajectories. The resulting trajectories are fully associative with the elements of the 3D model;

- generation of a control program in an intermediate code based on the ISO standard;

- conversion of the control program into the codes of a specific CNC system using postprocessors. The basic delivery package includes postprocessors for the following systems: Mayak 600T, NTs-31, FANUC Series MODEL D, SINUMERIK 802D, FAGOR CNC 8035T;

- visualization of processing in the window of the KOMPAS-3D system with imitation of material removal and control of the processing process.

- All operations are performed in the workspace of the KOMPAS-3D system using its interface elements (property panel, tab in the construction tree, toolbar). “CNC module. Turning” functions as part of the 32 and 64-bit versions of KOMPAS-3D.

The application has a large set of multi-pass, turn-drill and thread-cutting strategies. The following types of processing are supported:

- multi-pass – external turning, boring, trimming, multi-pass groove;

- contour – contour turning (as a rule, finishing);

- groove – a simple groove parallel to the coordinate axes;

- drilling – single and multi-pass drilling, centering, holemaking with an axial tool;

- threading with a cutter – multi-pass threading with a cutter (cylindrical, conical, face);

- threading with a die / tap – threading with a die or tap;

- cut – cut, including with a periodic withdrawal of the cutter.

Application features:

- use of parameterized models of tools and machine tools. The basic package includes a set of ready-made 3D models of tools and fixtures. At the same time, it is possible for the user to create their own models;

- using the Python scripting language for editing and developing postprocessors;

- the possibility of including CNC machine cycles in the control program.

Requires for work: KOMPAS-3D