CNC module. Milling

CNC module. Milling

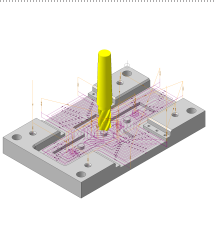

CNC module. Milling is a CAM application integrated into the KOMPAS-3D 3D modeling system. The application is designed for programming 3-axis machining on CNC milling machines.

The initial geometric information for creating a control program is the design model of the part created directly in the KOMPAS-3D system. This simplifies the work of the process engineer, who uses only one system, is not distracted by third-party applications, and has full confidence in the accuracy of the data from which the control program is developed.

The application allows you to create a processing plan, starting with the choice of a post-processor, workpiece, tool and fixtures, ending with the generation of a control program in the codes of the CNC system using a post-processor.

The main features of the application:

- automatic calculation of milling paths for 3-axis machining;

- generation of a control program in G-code based on the ISO standard;

- visualization of processing in the window of the KOMPAS-3D system;

- postprocessing.

All operations are performed in the workspace of the KOMPAS-3D system using elements of its interface. Machining elements are automatically recognized from the 3D model, which facilitates the formation of a three-dimensional machining area. Elements such as pockets, through grooves, holes, chamfers are recognized. Implemented automatic detection of areas of residual material from previous treatments at Z-levels. The residual material is determined in the corners or in the areas of the processing area where the cutter did not pass through the diameter. You can use model faces and edges, 3D curves, and sketch curves as datums. If the model is changed, the application will also change the program for the CNC machine.

Supported milling strategies:

- Milling at Z-levels – milling pockets and slots with a breakdown of the machining area into horizontal levels. At each level, a processing trajectory is formed with the possibility of using three schemes: equidistant, zigzag, line.

- Milling at Z-levels – Removal of residual material after milling at Z-levels.

- Plane – milling horizontal planes (a special case of milling at Z-levels).

- Contour – processing along a three-dimensional contour. The strategy can also be used to select a manually defined toolpath (for example, drawn in a sketch or built with 3D curves), including for 3D machining.

- Holemaking – processing of one or more holes, as well as round manholes.

- Cutting threads in holes.

Application features:

- use of parameterized models of tools and machine fixtures, with the ability to create your own models;

- using the Python scripting language for editing and developing postprocessors;

- the possibility of including in the control program machine cycles of CNC systems, as well as subroutines for processing the same elements.

Requires for work: KOMPAS-3D